The most common grades of stainless steel used to fabricate stainless tubing are 304 and 316 stainless steel. These grades are used for their extremely high corrosion resistance as well as their ability to be used in applications requiring sanitary grade materials. Read More…

Cada Stainless & Alloys has the stainless steel tubing that you need. We also specialize in the supply of stainless steel strips and coils, providing many finishing options, processing options, and other customization options.

Welded Tubes has a variety of tube shapes and tube sizes: squares, rectangles, hexes, octagons, etc., including many metric OD's. We make automotive, retail, safety, and medical tubing. Our steel tubing is suitable for any applications, including for high-end consumer products; it is high strength, made to tight tolerances, and aesthetically pleasing.

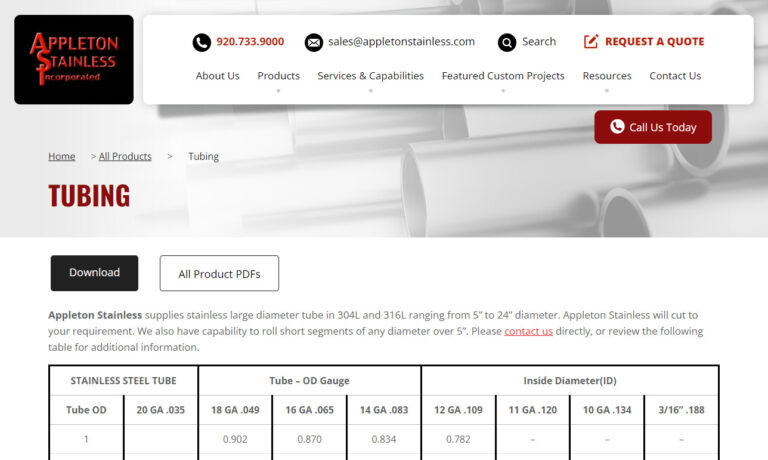

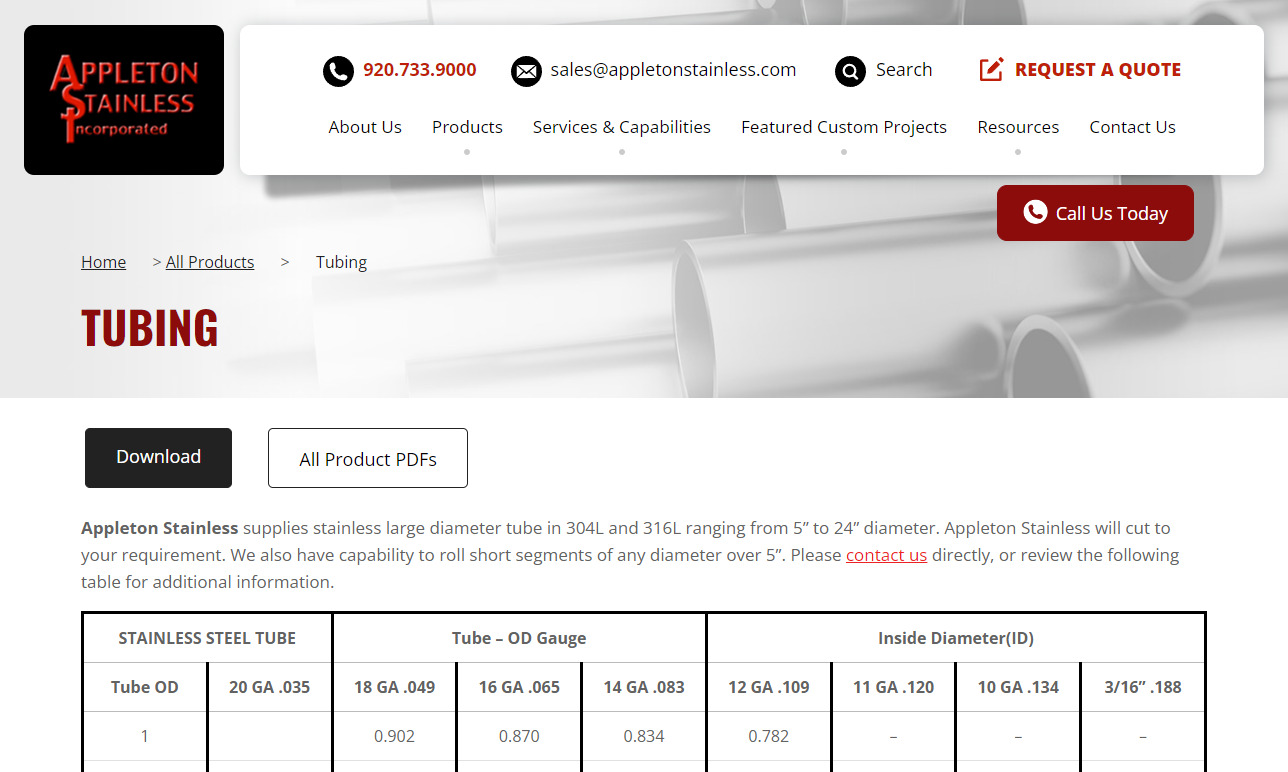

Welcome to Appleton Stainless Incorporated, where we pride ourselves on our expertise in providing high-quality stainless steel tubing solutions to meet the diverse needs of our clients. With years of experience and a commitment to excellence, we have established ourselves as leaders in the industry, delivering innovative products and services tailored to exceed our clients' expectations. Our...

You’ll find the finest structural and ornamental polished stainless steel tubing at Century Tube Corporation! This stainless tubing manufacturer solves a broad range of stainless steel tube applications in a variety of industries. Discover the complete capabilities of one of the oldest and strongest stainless steel companies!

More Stainless Tubing Manufacturers

Benefits of using stainless steel for tube fabrication include the ease of cleaning, low maintenance and long run cost-effectiveness. Even though stainless steel may require a higher initial cost than other metals, maintenance and replacement costs are lower. In addition, stainless tubing is less expensive than titanium, which is a metal with similar properties and applications. Mainly used in the medical industry, stainless tubing is used is referred to as hypodermic tubing, and is the medium for transferring medicine from a bottle to under the skin and into the bloodstream.

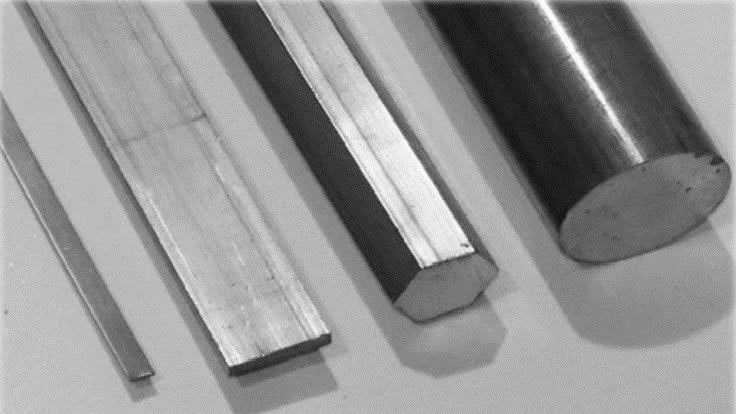

Stainless steel is used because its smooth and crack-free surface is very easy to sterilize. Stainless tubing is also used in a variety of applications in the dental, automotive, petrochemical, papermaking, and semiconductor industries, to name a few. While stainless tubing is usually round, square types are often manufactured to make stepladders, display racks and bar foot railings.

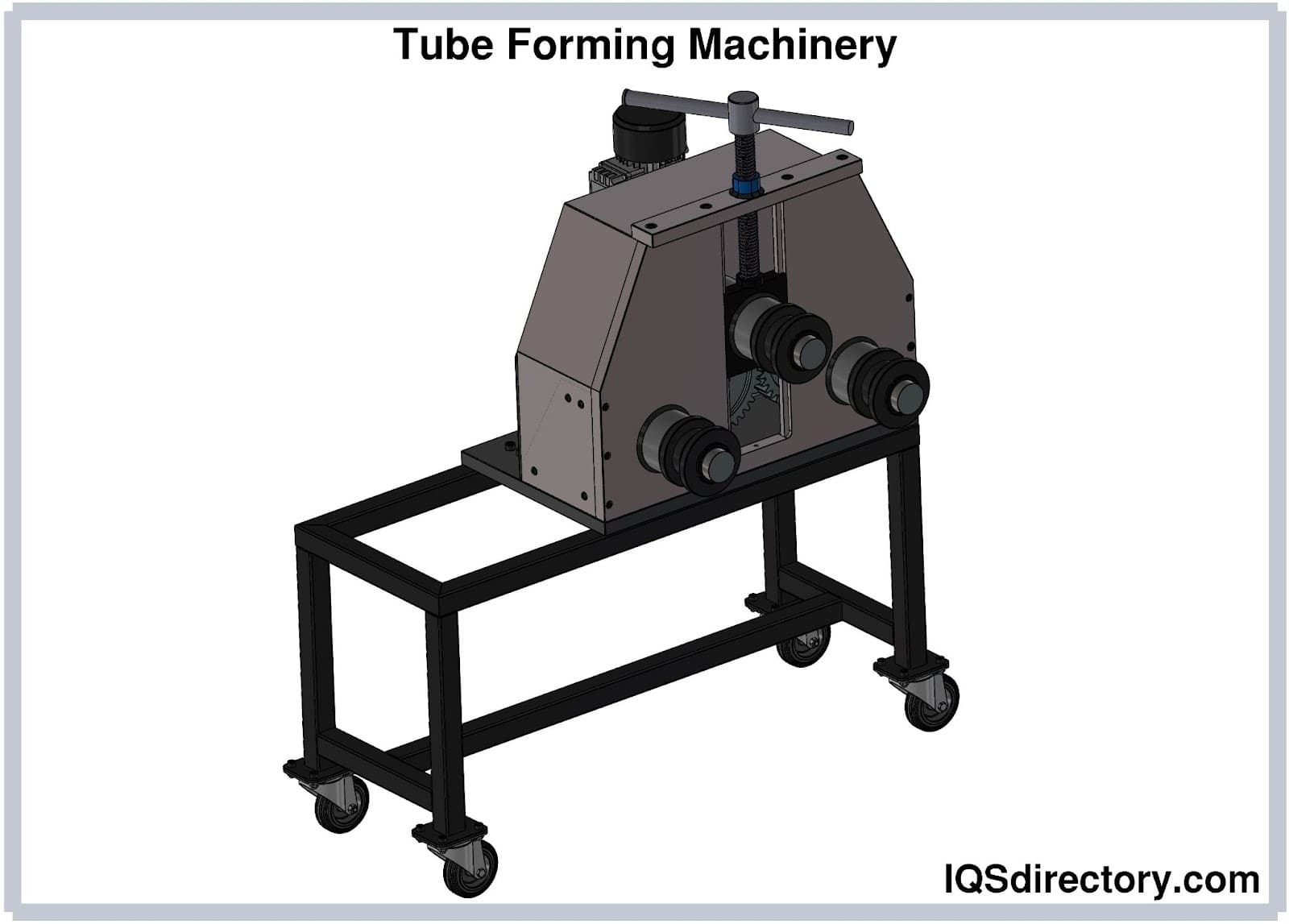

Stainless tubing is constructed through welding or seamless tubing procedures. Welding involves roll forming stainless steel and connecting the formed portions along a seam through fusion. Seamless tubing, in comparison, involves the creation of stainless steel tubing through piercing a round blank. In general, welding achieves a higher degree of precision without secondary operations. The degree of precision required, however, depends on the industrial application of the tubing. Another method of fabricating stainless tubing is through extrusion.

Perhaps the most easily available type is the seamless stainless steel pipe or tube, which is formed by extrusion. In extrusion, a solid billet is drawn over a piercing rod, which creates a hollow shell without any seams, unlike welding, where seams are unavoidable. Seamless tubing and piping is the most reliable when it comes to retaining high amounts of pressure, as it is much less likely to split. The use of stainless steel in the production of tubing is widespread due to the advantageous properties of stainless steel.

Stainless steel is the most common material used in the manufacturing of tubing, providing excellent corrosion resistance and little required maintenance and cleaning. Stainless tubing is also cost-effective in the long run. Even though stainless steel may require a higher initial cost than other metals, maintenance and replacement costs are lower.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services