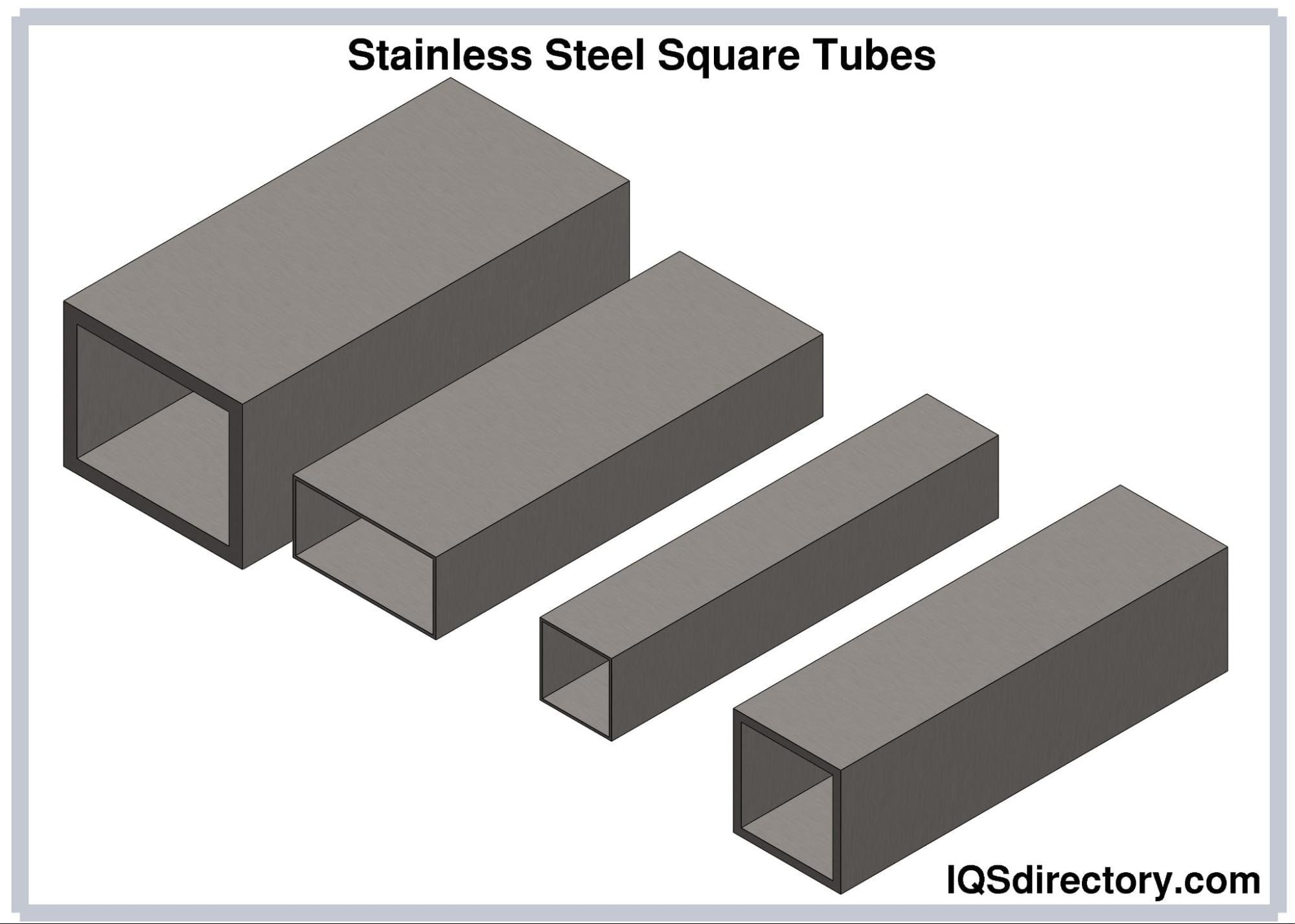

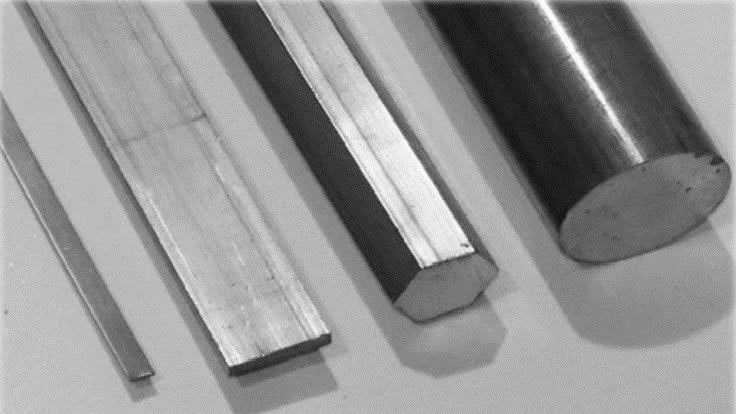

Several sizes and gauges are available for this structural/ornamental grade tube. Square stainless steel tube can be used for framing, bracing, supports, and mechanical parts, as well as for decorative trims and architectural accents because it is corrosion-resistant and weldable. In addition, steel tubes are essential to fabricating pipes for various uses, including heating and plumbing systems, highway engineering, automobile manufacturing, and even medicine. Steel tubes are made from raw materials such as iron, aluminum, carbon, manganese, titanium, vanadium, and zirconium (for surgical implants and heart valves). Read More…

Cada Stainless & Alloys has the stainless steel tubing that you need. We also specialize in the supply of stainless steel strips and coils, providing many finishing options, processing options, and other customization options.

Welded Tubes has a variety of tube shapes and tube sizes: squares, rectangles, hexes, octagons, etc., including many metric OD's. We make automotive, retail, safety, and medical tubing. Our steel tubing is suitable for any applications, including for high-end consumer products; it is high strength, made to tight tolerances, and aesthetically pleasing.

Welcome to Appleton Stainless Incorporated, where we pride ourselves on our expertise in providing high-quality stainless steel tubing solutions to meet the diverse needs of our clients. With years of experience and a commitment to excellence, we have established ourselves as leaders in the industry, delivering innovative products and services tailored to exceed our clients' expectations. Our...

You’ll find the finest structural and ornamental polished stainless steel tubing at Century Tube Corporation! This stainless tubing manufacturer solves a broad range of stainless steel tube applications in a variety of industries. Discover the complete capabilities of one of the oldest and strongest stainless steel companies!

More Stainless Steel Square Tubing Manufacturers

Manufacturing Process of Steel Square Tubes

Raw steel must first be transformed into weldable materials such as ingots, blooms, slabs, or billets to make steel tubes. Next, a pipeline must be built on a manufacturing line, and the pipe must then be formed into the required result.

Molten steel is produced by melting iron ore and coke, a carbon-rich liquid made from heated coal, into a liquid in a furnace and blasting it with oxygen. This substance is cooled into steel ingots, which are substantial castings molded between rollers under intense pressure. Some ingots are run through steel rollers, which stretch them into thinner, longer pieces to produce blooms, which are intermediates between steel and iron. Additionally, they are rolled between stacked rollers that shape the blooms into rectangular-sectioned steel pieces known as slabs.

In a procedure known as coining, further rolling mechanisms flatten blooms into billets. These are even longer and thinner pieces of metal with round or square cross-sections. Flying shears cut the billets at exact angles to enable stacking and seamless pipe formation. Slabs are thinned into skelp, which are narrow strips of ribbon up to 0.25 miles (0.4 kilometers) in length, after being heated to a temperature of around 2,200 degrees Fahrenheit (1,204 degrees Celsius), making them pliable. The steel is then cleaned with sulfuric acid tanks, followed by cold and hot water, before being transferred to facilities that make pipes.

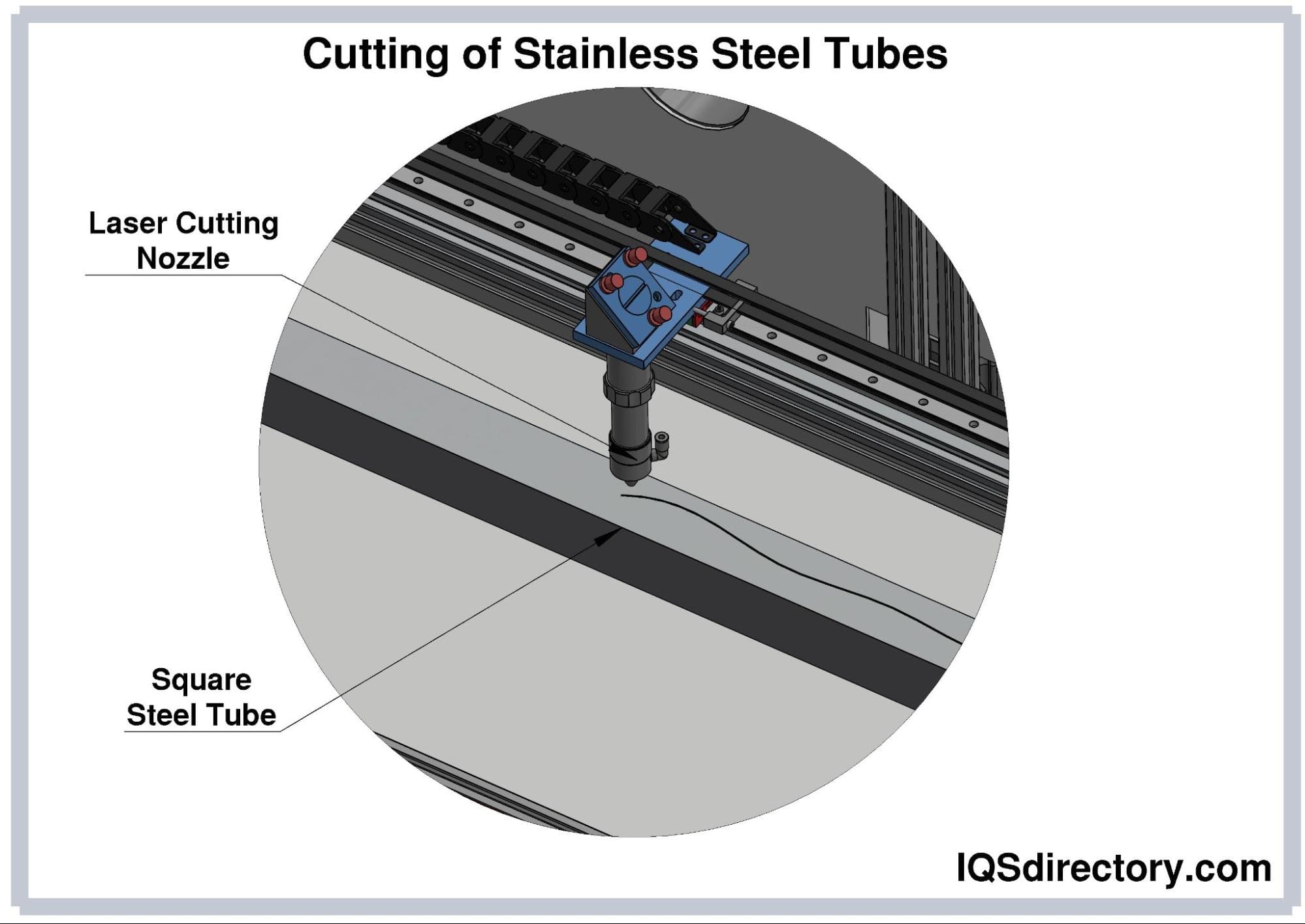

For welded pipes, skelp is unwound and put through rollers on an unwinding machine to cause the edges to curl and form pipes. Before being tightened by a high-pressure roller, the ends are sealed together by welding electrodes using an electric current. This method has a maximum production rate of 1,100 feet (335.3 meters) of pipe per minute. Square billets are stretched with a hole in the middle during the high-pressure rolling and heating process to create seamless pipes. Finally, the pipe is pierced in rolling mills to achieve the correct thickness and shape.

Straightening, threading (which involves carving narrow grooves into the ends of pipes), galvanizing, or any other additional processing required for the pipe's intended use may be done. Galvanization typically comprises electrochemical and electrodeposition procedures of zinc coatings to protect the metal from corrosive substances like salt water.

The method prevents hazardous oxidizing substances in the air and water. Zinc reacts with oxygen as an anode to produce zinc oxide, which combines with water to produce zinc hydroxide. When exposed to carbon dioxide, these zinc hydroxide molecules transform into zinc carbonate. Finally, zinc is shielded by a thin, impermeable, insoluble coating of zinc carbonate.

Since hot-dip weakens the base metal, electro galvanization, a thinner variant, is typically employed on auto parts that need rust-proofing paint. When stainless components are galvanized with carbon steel, stainless steel is produced.

Applications of Stainless Steel Square Tubing

- The ideal choice for home entry gates is square tubes. The sleek square tube's beauty and finish, not to mention its practicality, are surely desired by homeowners wishing to finish their ultramodern or contemporary homes. Of course, any residential gate will typically increase the property's protection, but square tubing ups the ante by adding a decorative feature. For instance, cold-formed square tubes can be changed into many designs because of their great ductility and malleability. In addition, they can be equipped with access control, turnstiles (for commercial buildings), and other contemporary home solutions like automatic gate openers.

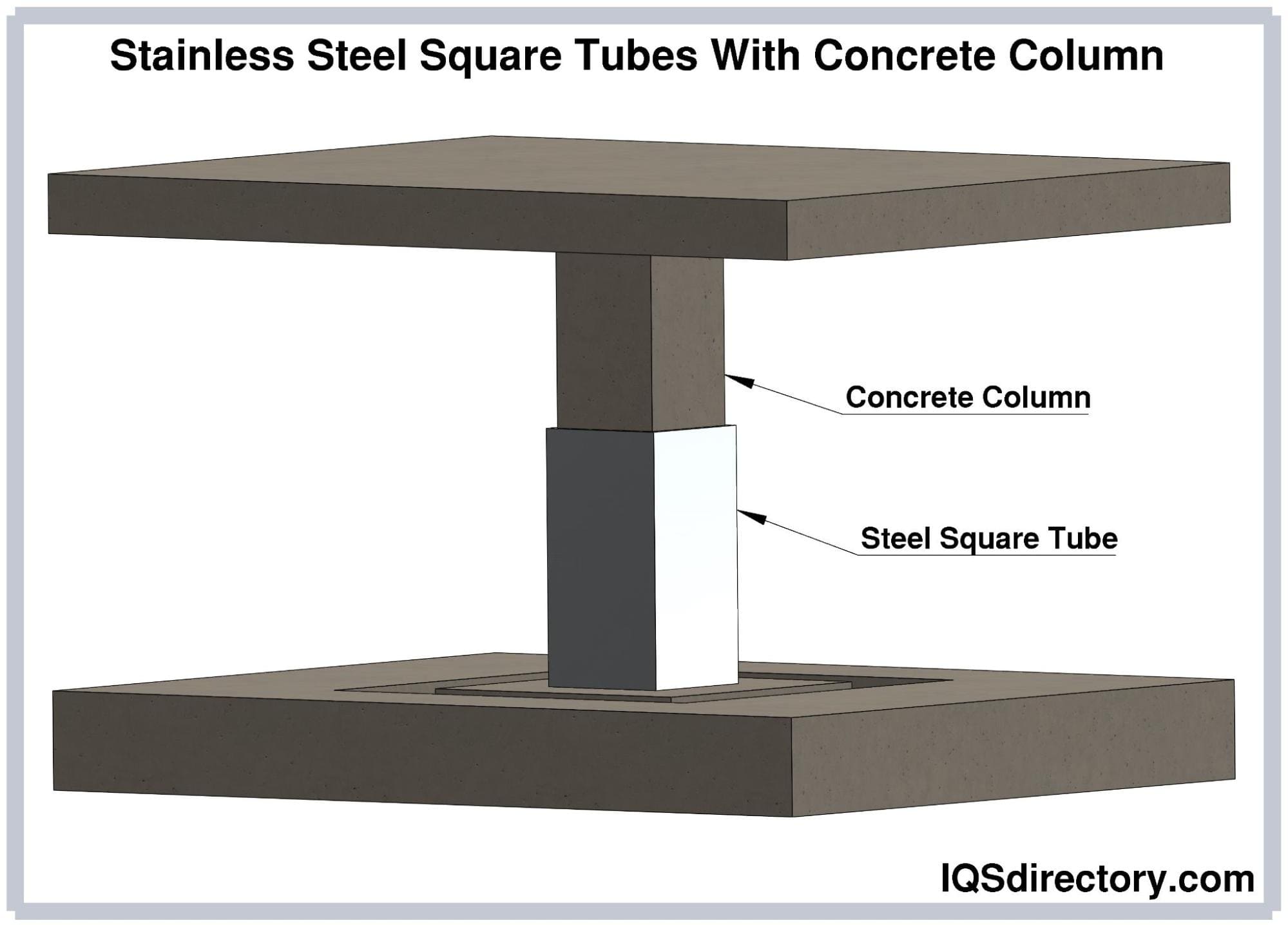

- A network of building columns can be created using square tubes, which are structural steel or metal goods. Since square tubes can support a variety of loads despite the material variance, this is one of its best applications. Contrary to popular opinion, the square tubing's hollow design may handle such loads. Due to the tube's small weight, it is preferable to other solid-shaped building materials of a similar nature. The tubes now have a superior strength-to-weight ratio that is on par with that of PVC, wood, or pure concrete. Square tubes can be used to create full-fledged column constructions on their own, but they can also be used in conjunction with concrete to fortify the framework and increase tensile strength. Due to its semi-brittle nature, concrete benefits from using square metal tubing by being better able to withstand physical impacts while lowering construction costs.

Choosing the Right Stainless Steel Square Tubing Supplier

To make sure you have the most productive outcome when purchasing stainless steel square tubing from a stainless steel square tubing supplier, it is important to compare at least 4 to 5 companies using our stainless steel square tubing directory. Each stainless steel square tubing supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the supplier for more information or request a quote. Review each stainless steel square tubing company website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple stainless steel square tubing businesses with the same message.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services