Often used in industrial, commercial and even residential settings, 304 stainless steel possesses the high tensile strength and durability that virtually all steels are known for, as well as having excellent forming and welding characteristics. Read More…

Cada Stainless & Alloys has the stainless steel tubing that you need. We also specialize in the supply of stainless steel strips and coils, providing many finishing options, processing options, and other customization options.

Welded Tubes has a variety of tube shapes and tube sizes: squares, rectangles, hexes, octagons, etc., including many metric OD's. We make automotive, retail, safety, and medical tubing. Our steel tubing is suitable for any applications, including for high-end consumer products; it is high strength, made to tight tolerances, and aesthetically pleasing.

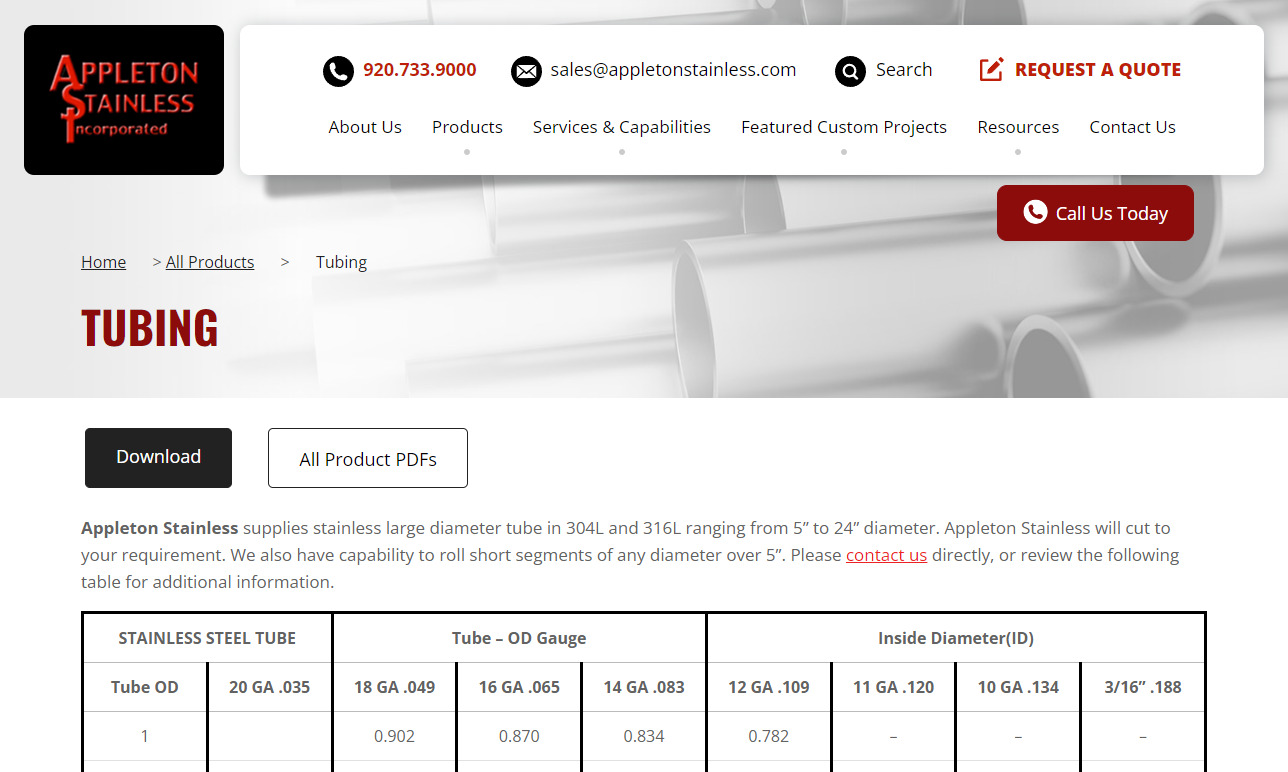

Welcome to Appleton Stainless Incorporated, where we pride ourselves on our expertise in providing high-quality stainless steel tubing solutions to meet the diverse needs of our clients. With years of experience and a commitment to excellence, we have established ourselves as leaders in the industry, delivering innovative products and services tailored to exceed our clients' expectations. Our...

You’ll find the finest structural and ornamental polished stainless steel tubing at Century Tube Corporation! This stainless tubing manufacturer solves a broad range of stainless steel tube applications in a variety of industries. Discover the complete capabilities of one of the oldest and strongest stainless steel companies!

More 304 Stainless Steel Tubing Manufacturers

Grade 304 stainless steel has a relatively high melting point of 1,400 to 1,450 degrees C and is extremely resistant to wear and corrosion. For these reasons and more, this is a popular material used in the manufacture of steel tubing for a number of environments such as petrochemical, water treatment, pulp and paper, automotive, medical, dental, semiconductor, food processing and aerospace industries among others.

Products include fuel lines, architectural supports and even medical implants and instruments as 304 is an easily sanitized surgical grade austenitic steel. Although this alloyed tubing has a higher initial cost than many other options, the elemental structure significantly increases tube longevity, reducing long term expenses such as maintenance and replacements. While 304 stainless steel will eventually need repair or replacement, this material is easily melted down and recycled, further reducing costs and waste.

Originally known as 18/8 stainless steel, in reference to its nominal composition being 18% chromium and 8% nickel, the elemental content of 304 stainless steel is actually variable. While iron and carbon are inherently present, nickel content ranges from 8 to 18 percent while chromium content is between 18 and 20 percent.

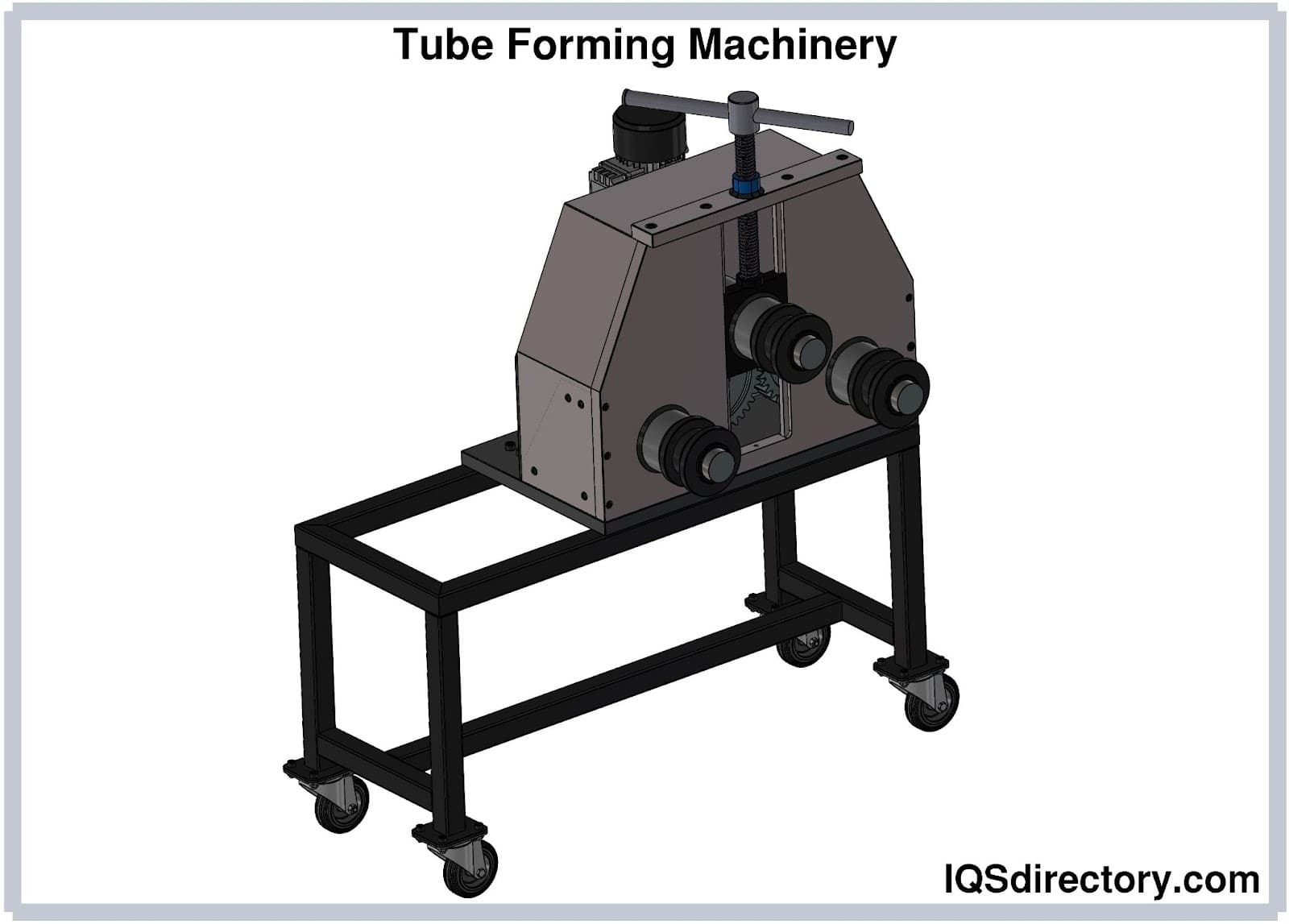

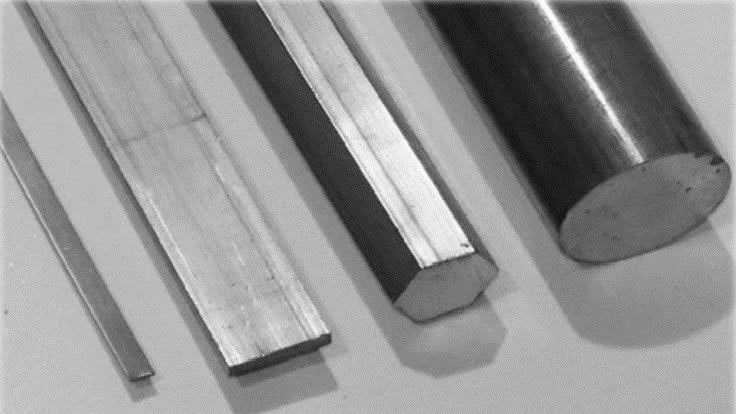

Low carbon variants known as type 304L have improved weldability though high carbon variants, 304H, perform better at elevated temperatures. The specific alloy selected for a given tubing application is determined by the intended use. The manufacturing process must also be taken into account. Common processes in the production of stainless steel tubing include welding, seamless tubing via extrusion and metal spinning.

Seamless tubing is preferred in instances where an edge could be caught and slow or stop production while welded tubes offer a higher degree of precision. The process and particular stainless steel alloy should be carefully considered with regards to the intended use of a 304 stainless steel tube.

Further considerations include inner and outer diameters, length, wall thickness, pressure rating, maximum bend radius, temperature range and finishing. As tubing is often a stock shape intended for secondary operations such as roll forming, the machining possibilities of this particular alloy and its variants should also be suited to the needs of the finished product.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services