Stainless steel is a corrosion-resistant alloy. The chromium in stainless steel creates a coating that shields the metal and self-heals in oxygen. Stainless steel is often rolled or formed into tubes or pipes for use in multiple industries. The circular shape of stainless steel pipes makes them incredibly strong. Read More…

Cada Stainless & Alloys has the stainless steel tubing that you need. We also specialize in the supply of stainless steel strips and coils, providing many finishing options, processing options, and other customization options.

Welded Tubes has a variety of tube shapes and tube sizes: squares, rectangles, hexes, octagons, etc., including many metric OD's. We make automotive, retail, safety, and medical tubing. Our steel tubing is suitable for any applications, including for high-end consumer products; it is high strength, made to tight tolerances, and aesthetically pleasing.

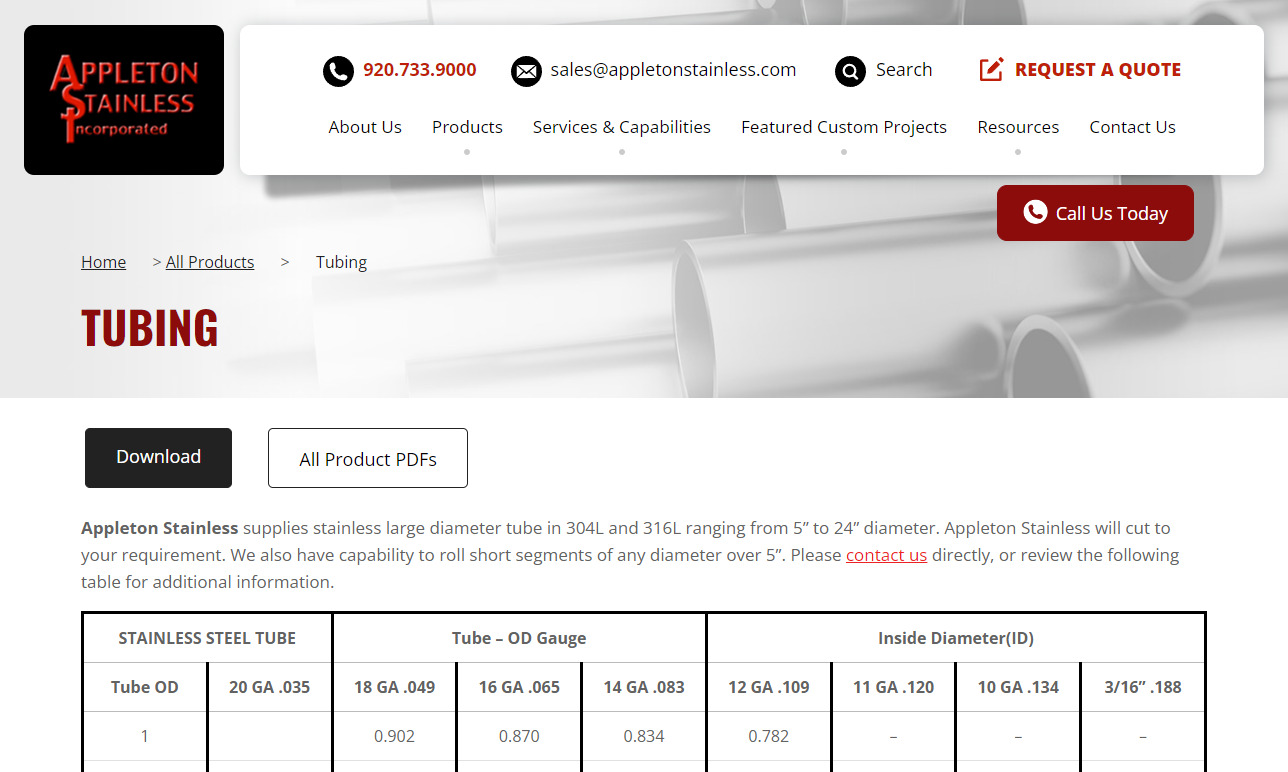

Welcome to Appleton Stainless Incorporated, where we pride ourselves on our expertise in providing high-quality stainless steel tubing solutions to meet the diverse needs of our clients. With years of experience and a commitment to excellence, we have established ourselves as leaders in the industry, delivering innovative products and services tailored to exceed our clients' expectations. Our...

You’ll find the finest structural and ornamental polished stainless steel tubing at Century Tube Corporation! This stainless tubing manufacturer solves a broad range of stainless steel tube applications in a variety of industries. Discover the complete capabilities of one of the oldest and strongest stainless steel companies!

More Stainless Steel Pipe Manufacturers

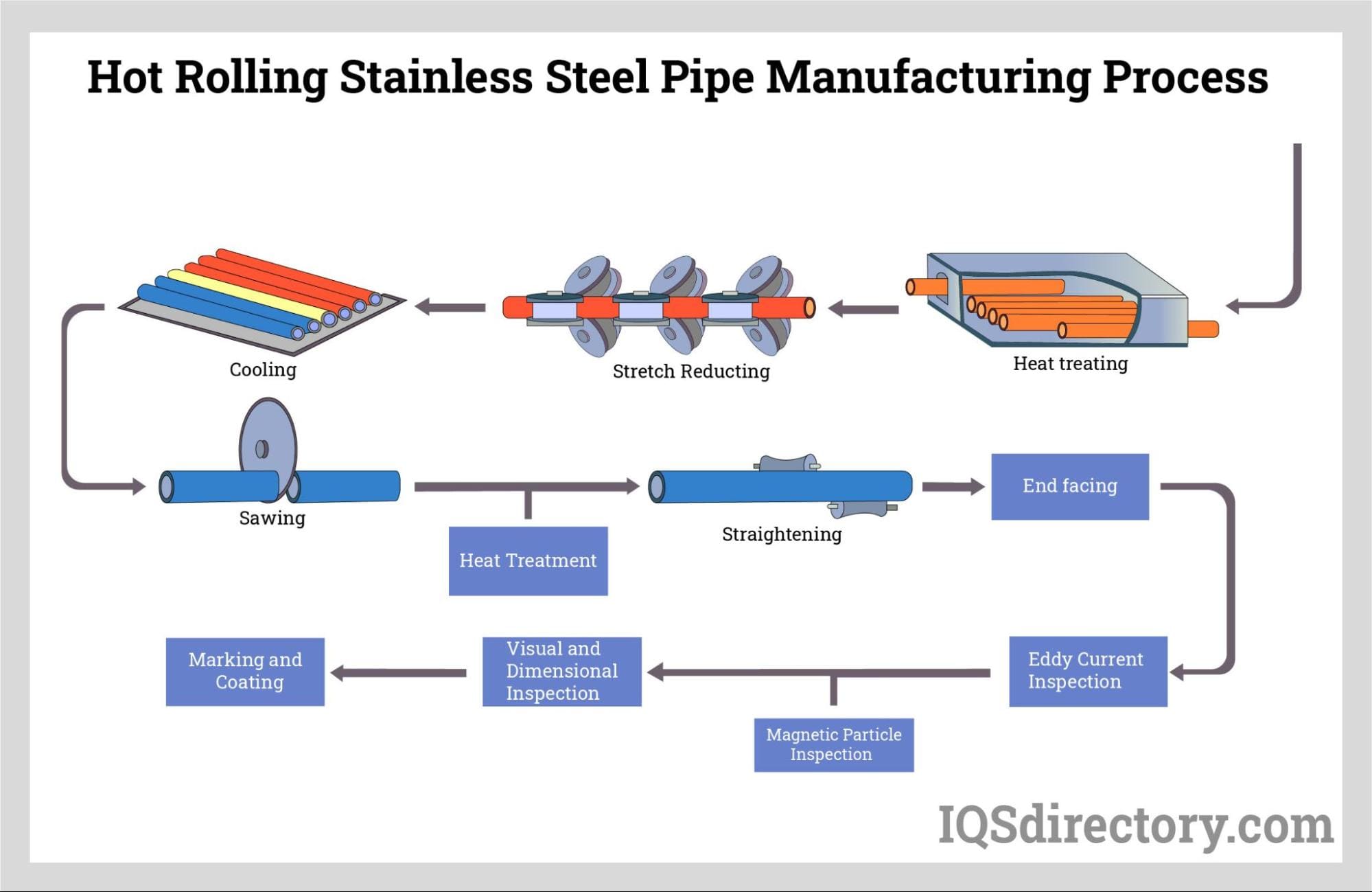

How Stainless-steel Pipes Are Made

Stainless steel is created from nickel, iron ore, chromium, silicon, molybdenum, and other raw components fused together. The manufacturing process of the stainless-steel pipes goes down in several stages, which can be done by hot rolling or cold rolling.

Automatic rolling mills are used to make hot-rolled stainless steel seamless pipes. First, manufacturers take a solid tube blank and inspect the surface to remove defects. Next, the solid tube blank is cut to order, heated in a heating furnace, and punched.

Manufacturers use cold rolling or cold drawing to make smaller seamless pipes. Cold-rolling is usually done on a two-roll mill. Stainless steel tubes with small diameters can also be made through extrusion.

Types of Stainless Steel used In Piping

There are several stainless steel pipes present in the market today. When the microstructure of stainless steel is altered, its characteristics also change. Stainless steel can be categorized as austenitic, martensitic, duplex, super duplex, precipitation-hardened, and ferritic.

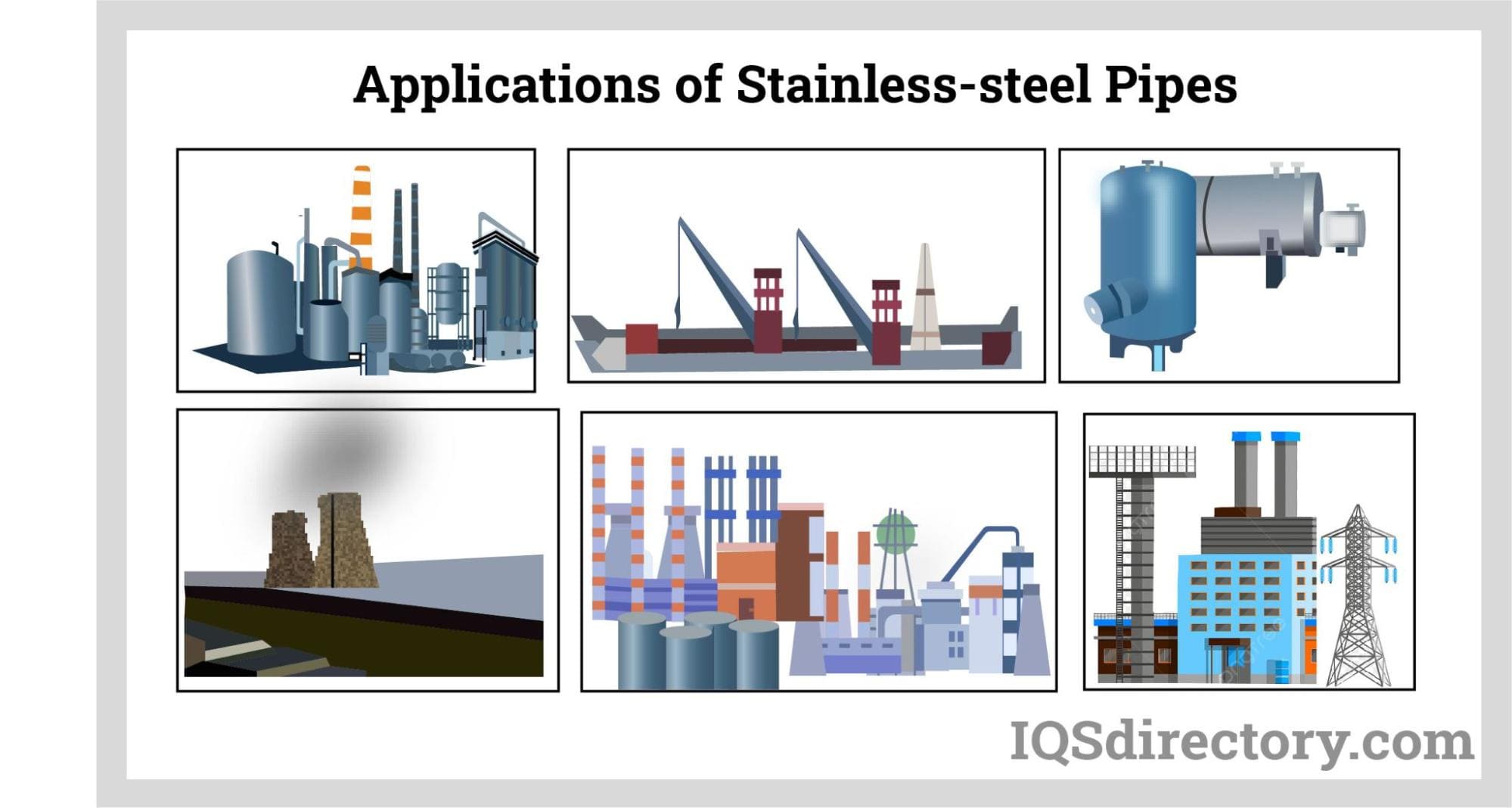

Applications

Stainless steel is frequently used for desalination because of its strong corrosion resistance. Sanitizing chemicals won’t destroy stainless steel pipes, so pharmaceutical firms use them extensively. Stainless steel pipes are used in the dairy industry and food processing.

Stainless steel pipes are an obvious choice for low maintenance and corrosion-resistant applications. These pipes can be found in products like heat exchangers, fluid piping, LP/HP heaters, automobiles, evaporators, digesters, and surface condensers.

Advantages of Stainless-Steel Pipes

- They have a higher strength-to-weight ratio.

- Compared to steel, stainless steels are significantly more resistant to erosion-corrosion brought on by high flow rates and particulate matter. As a result, manufacturers can pump various media through stainless steel pipes at high speeds without damaging the pipes.

- Compared to corroded or old cement-lined steel pipes, stainless steel maintains low hydraulic friction qualities, reducing water pressure losses and lowering pumping costs.

- Pipelines are easier to handle and install because stainless steels have good elasticity and can be bent and welded into lightweight shapes.

Disadvantages of Stainless-Steel Pipes

- Stainless steel pipes are much more expensive.

- They have very poor thermal conductivity.

Choosing the Proper Stainless Steel Pipes Manufacturer

To make sure you have the most positive outcome when purchasing stainless steel pipes from a stainless steel pipe manufacturer, it is important to compare at least 4 to 5 manufacturers using our stainless steel pipe directory. Each stainless steel pipe manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each stainless steel pipe business website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple stainless steel pipe companies with the same quote.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services