Commonly abbreviated CSST, this particular type of tubing is used predominately in gas distribution industries and those industrial, commercial and residential applications in which gas transport, gas heating and appliances are commonly employed. Read More…

Cada Stainless & Alloys has the stainless steel tubing that you need. We also specialize in the supply of stainless steel strips and coils, providing many finishing options, processing options, and other customization options.

As stainless steel producers, Source 21 specializes in hard-to-find materials. We produce all tempers plus commercial and exotic stainless steel. You choose from our inventory or we can custom produce to your needs. An ISO 9001:2000 registered company; we maintain comprehensive inventories at our various US processing locations to facilitate quick shipments. Check out our website!

All Metal Sales is a leading-supplier of stainless steel tubing, stainless steel pipe, thin wall tubing, precision tubing and small diameter tubing. We focus on superior customer service, premium quality and quick turnaround times in order to best meet your needs.

More Corrugated Stainless Steel Tubing Manufacturers

Corrugated Stainless Steel Tubing (CSST): The Ultimate Guide to Flexible Gas Piping Solutions

Corrugated stainless steel tubing, commonly referred to as CSST, has rapidly gained popularity across residential, commercial, and industrial sectors due to its outstanding performance and versatility as a gas piping solution. As modern infrastructure evolves, the demand for safe, reliable, and efficient gas distribution systems has never been higher. CSST stands out as a leading choice for natural gas and propane installations, offering a host of benefits over traditional rigid gas pipes.

What Is Corrugated Stainless Steel Tubing (CSST)?

CSST is a flexible, thin-walled metallic tubing manufactured from high-grade stainless steel. It features a unique corrugated design that allows it to bend and flex easily, making it ideal for routing around obstacles and through tight spaces. The tubing is typically covered in a durable plastic jacket, available in black or yellow, which provides additional protection and helps installers visually distinguish gas piping from other utility lines.

This innovative piping system is engineered for use with both natural gas and liquefied petroleum gases (LPG), such as propane, and is suitable for both low-pressure and high-pressure gas distribution networks. Thanks to its superior corrosion resistance, CSST can be used in a wide variety of environments, from residential basements to industrial facilities, ensuring long-term reliability and safety.

Key Benefits of Corrugated Stainless Steel Tubing

Many gas professionals and building owners are transitioning to CSST due to the numerous advantages it offers over traditional black iron or copper pipes. Below, we explore the top reasons to choose CSST for your next gas piping project:

- Exceptional Flexibility and Easy Installation: CSST can be routed around corners, through walls, and across joists with minimal need for elbows or couplings. This reduces installation time, labor costs, and potential points of failure.

- Corrosion Resistance: Stainless steel’s high chromium content (at least 10%) provides remarkable resistance to rust, oxidation, and other forms of corrosion. This makes CSST ideal for use in damp or corrosive environments.

- Reduced Risk of Gas Leaks: Fewer joints and connections mean fewer opportunities for leaks. The continuous tubing design, combined with robust plastic jacketing, offers an added layer of safety.

- Lightweight and Space-Saving: CSST's thin-walled construction and compact size simplify transport, storage, and handling, while also allowing for more streamlined installations in confined spaces.

- Versatility: Suitable for both new builds and retrofitting projects, CSST can be used in residential homes, commercial buildings, and industrial sites.

- Cost Savings: The reduced need for fittings and faster installation translate to lower overall project costs.

Because stainless steel is highly resistant to corrosion, tubing of this nature may be used for both gases under pressure and volatile gases. The dual layered tubing allows for easy shaping and bending which not only reduces the need for stainless steel pipe fittings and other expensive connectors, but in so doing lessens the possibility of costly and potentially hazardous gas leaks.

The flexibility, lightweight and smaller size of CSST also allows for easier installation thereby reducing labor costs in addition to savings related to the decrease in material usage. The plastic exterior coating comes in black or yellow to suit aesthetic needs, though the majority of the tubing is inside of walls and therefore not visible.

How Is CSST Installed? Understanding Methods and Best Practices

Installed in similar fashion to wiring, CSST lines are generally run along floor and ceiling joists. Corrugated stainless steel is rarely seen in its interior applications, though the exterior connection to the gas source or meter is often visible. A central manifold or parallel configuration with multiport manifolds allows for a several lines to be run to individual appliances as well as easy expansion of the system if needed. This thin-walled metallic tubing consists of two layers.

Modern installation practices for CSST focus on safety, efficiency, and compliance with local building codes. Qualified gas fitters or licensed plumbers should always carry out CSST installations to ensure adherence to manufacturer guidelines and regulatory standards.

- Routing and Support: CSST is routed along structural elements such as joists, studs, and beams. It must be properly supported to prevent sagging and physical stress.

- Connection to Appliances: Specialized fittings and adapters are used to connect CSST to gas appliances, meters, and other system components. Secure connections are critical to prevent leaks.

- Bonding and Grounding: To protect against electrical hazards such as lightning strikes, CSST systems must be properly bonded and grounded according to local codes.

- Pressure Testing: After installation, the system should undergo rigorous pressure testing to confirm leak-free operation before being put into service.

- Labeling and Identification: The exterior plastic jacket (black or yellow) helps inspectors and installers identify gas lines and distinguish them from water, electrical, or HVAC conduits.

Material Composition and Structural Features of CSST

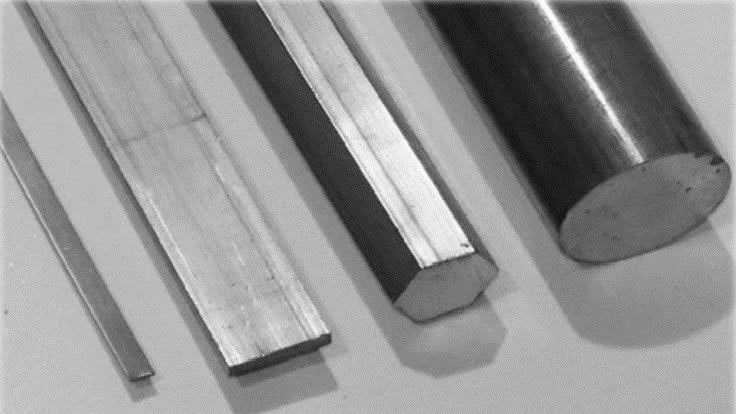

The interior layer is a continuous stainless steel coil, produced by either hot or cold rolling of alloyed steel strips. While all steel alloys contain iron and carbon, stainless steel in particular has a chromium content of at least 10%. Chromium is the element responsible for the high corrosion resistance of these coils necessary in many gas distribution applications. The exterior layer of corrugated stainless steel tubing is plastic.

This PVC covering lends not only flexibility to the piping, but also added protection against gas leaks should the stainless steel coils fail. As with all stainless steel tubing, corrugated stainless steel tubing comes in a variety of shapes and grades. Important considerations for the installation of CSST include inner and outer diameters, wall thickness, pressure rating, maximum bend radius, temperature range and finishing.

Comparing CSST vs. Traditional Gas Piping Systems

When evaluating gas piping options, many buyers and decision-makers weigh the advantages of CSST against traditional materials like black iron, copper, and rigid steel pipes. Below is a detailed comparison to help guide your selection process:

| Attribute | CSST | Black Iron Pipe | Copper Pipe |

|---|---|---|---|

| Flexibility | Highly flexible, bends easily | Rigid, requires many fittings | Some flexibility, but limited |

| Corrosion Resistance | Excellent (stainless steel) | Moderate (prone to rust) | Good (prone to pitting over time) |

| Installation Speed | Fast, fewer joints needed | Slow, labor-intensive | Moderate |

| Leak Risk | Low (fewer joints) | Higher (more connections needed) | Moderate |

| Weight | Lightweight | Heavy | Lightweight |

| Material Cost | Moderate | Low | High |

| Labor Cost | Low | High | Moderate |

| Application Versatility | High (suitable for many uses) | Limited to straight runs | Good |

This comparison illustrates why CSST is often the preferred choice for modern gas piping applications, especially where speed, adaptability, and long-term reliability are essential.

Where Is CSST Used? Top Applications and Use Cases

CSST is valued for its adaptability and broad range of practical applications. Its most common uses include:

- Residential Gas Distribution: Supplying natural gas or propane to home appliances such as furnaces, water heaters, stoves, fireplaces, and outdoor grills.

- Commercial Buildings: Safely routing gas to boilers, HVAC systems, kitchen ranges, dryers, and backup generators in restaurants, hotels, and office complexes.

- Industrial Facilities: Reliable gas delivery for process heating, manufacturing equipment, and large-scale generators.

- Retrofit Projects: Upgrading older properties with modern, code-compliant gas piping while minimizing disruption to existing structures.

- Multi-Unit Housing: Distributing gas to apartments, condominiums, and townhomes via centralized or distributed manifold systems.

- Custom and Modular Construction: Facilitating efficient gas line routing in prefabricated or modular buildings.

What Should You Consider Before Buying CSST?

For property owners, contractors, and engineers exploring CSST as a gas piping solution, several key decision factors should inform your purchase and installation:

- System Design: Determine the gas load requirements, the number and type of appliances, and the most efficient routing for the tubing.

- Size and Specifications: Select the appropriate inner and outer diameter, wall thickness, and pressure rating based on your project’s needs and local code requirements.

- Product Certification: Ensure the CSST meets recognized standards such as ANSI LC-1 or equivalent, which certify the tubing for gas distribution safety and performance.

- Installer Qualifications: Only use licensed professionals with experience in CSST installations to ensure safe and code-compliant work.

- Bonding and Grounding: Confirm that your system will be properly bonded and grounded to reduce the risk of fire or electrical damage.

- Manufacturer Warranty: Review the warranty terms provided by the tubing manufacturer and ensure that all installation requirements are met to maintain coverage.

Buyers should also research the reputation of different CSST brands and consult with suppliers about availability, pricing, and support for their specific project needs.

Industry Standards, Certifications, and Safety Regulations

Safety is paramount when it comes to gas piping. CSST products are subject to rigorous industry standards and building codes designed to protect property and occupants. In North America, the most widely recognized certification for CSST is ANSI LC-1, which sets requirements for flexible gas piping systems. Many jurisdictions also require compliance with the International Fuel Gas Code (IFGC), National Fire Protection Association (NFPA) codes, and local building regulations.

Key safety considerations include:

- Proper Bonding: CSST systems must be adequately bonded to the building’s grounding system to prevent fires caused by lightning or electrical faults.

- Correct Installation: Only qualified professionals should install CSST, strictly following manufacturer and code requirements for routing, support, and connections.

- Routine Inspection: Periodic inspections are recommended to ensure ongoing safety and performance of the gas distribution system.

- Compatibility: Use only approved fittings and connectors designed specifically for the brand and type of CSST you are installing.

CSST Sizes, Grades, and Customization Options

Corrugated stainless steel tubing is available in a range of diameters, wall thicknesses, and grades to suit various applications. Common sizes include 1/2-inch, 3/4-inch, and 1-inch tubing, but larger or smaller sizes may be available for specialized use.

Grades of stainless steel used in CSST typically include 304 and 316 alloys, which offer excellent corrosion resistance and mechanical durability. Some manufacturers offer specialty grades for harsh environments or high-pressure applications.

Customization options include:

- Length: Tubing can be cut to precise lengths, reducing waste and ensuring a perfect fit.

- Color Coding: Jackets are available in yellow or black for easy identification or to meet local code requirements.

- Pre-Insulated Tubing: Some suppliers offer pre-insulated CSST for outdoor or cold-climate installations.

- Specialized Fittings: Compatible fittings and adapters for unique appliance connections or system configurations.

- Fire-Resistant Jackets: Enhanced safety for installations in high-risk areas.

Frequently Asked Questions about Corrugated Stainless Steel Tubing

Is CSST safe for use in homes and businesses?

Yes, when installed according to manufacturer instructions and local codes, CSST is a safe and approved method for gas distribution in residential, commercial, and industrial settings. Proper bonding, quality installation, and periodic inspections are essential for long-term safety.

How does CSST compare to flexible copper tubing?

While flexible copper tubing is sometimes used for short gas appliance connections, CSST is specifically engineered for whole-house or building-wide distribution. CSST offers superior corrosion resistance, flexibility, and is often easier and faster to install in large-scale projects.

What are the most common causes of CSST failures?

Most issues with CSST arise from improper installation, inadequate bonding, or physical damage. Always use qualified professionals and follow best practices to avoid these problems.

Can CSST be used outdoors?

Yes, many CSST products are approved for outdoor use, provided they are protected from UV exposure and physical impact. Pre-insulated and jacketed options are available for exterior applications.

How long does CSST last?

When properly installed and maintained, CSST can provide decades of reliable service. The corrosion-resistant properties of stainless steel, combined with durable plastic jacketing, offer excellent longevity even in challenging environments.

Making the Switch: Why Choose Corrugated Stainless Steel Tubing?

For contractors, engineers, and property owners seeking a modern, efficient, and reliable gas piping solution, corrugated stainless steel tubing offers a compelling array of advantages. Its exceptional flexibility, corrosion resistance, and safety profile make it an ideal choice for a wide variety of projects. Whether you’re upgrading an existing structure, designing a new building, or looking for a cost-effective solution to complex routing challenges, CSST delivers superior performance and peace of mind.

By reducing installation time, minimizing the need for additional fittings, and offering strong protection against leaks and corrosion, CSST is positioned at the forefront of gas piping technology. As energy codes and safety standards continue to evolve, investing in high-quality corrugated stainless steel tubing ensures that your gas distribution system meets today’s requirements and is ready for tomorrow’s demands.

To learn more about compatible fittings and advanced connection solutions, visit our page on stainless steel pipe fittings. Explore how a complete stainless steel piping system can transform your next gas installation, providing unmatched reliability, efficiency, and lasting value.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services